COLORED CRYSTAL FOILS

In addition to standard transparent crystal foils; colored crystal foils in white, black, cream, brown and gray are also available.

Colored crystal foils can be used in one step for non-metallic matte or glossy results. White colored lasers are used especially with transparent multicolor patterned hot stamping foils to obtain soft appearances on dark surfaces. Thus, multicolor foil colors that are expected to disappear due to the background color are protected with white laser and even unique soft appearances are obtained.

There is no need for additional hot stamping foil coloring in colors such as black and coffee. In addition, if desired, it becomes possible to apply transitional, deep effects with any foil on colored crystal foil that still maintains its adhesive feature with emboss, especially in leather printing.

Standart şeffaf lazer folyoların yanı sıra; beyaz, siyah, krem, kahverengi ve gri renkte renkli lazer folyolar da mevcuttur.

Renkli lazer folyolar, metalik olmayan mat veya parlak sonuçlar için tek adımda kullanılabilir. Beyaz renkli lazerler özellikle şeffaf multicolor desenli varaklarla koyu zeminler üzerinde soft görünümler elde etmek için kullanılmaktadır. Böylece zemin rengi nedeniyle kaybolması beklenen multicolor varak renkleri beyaz lazer ile korunmuş hatta benzersiz soft görünümler elde edilmiş olur.

Siyah ve kahve gibi renklerde ise ilave varak ile renklendirmeye gerek kalmaz. Ayrıca istenirse özellikle deri baskıda embos ile hala tutkal özelliğini koruyan renkli lazer üzerine herhangi bir varak ile geçişli, derinlikli efektler uygulanması mümkün hale gelir.

TEMPERATURE: 150°C

PRESSURE: 6 bar

CONTACT TIME: 5-6 sn

TEMPERATURE: 160°C

PRESSURE: 6 bar

SPEED: 3-5 m/min

LENGTH: 3 inch 200 m

WIDTH: 160 cm

Vary between 30 and 200 microns depending on the pattern.

Genuine/suede/nubuck leather

Polyester/cotton based fabrics

Elastic/knitted/woven fabrics

TEMPERATURE: 150°C

PRESSURE: 6 bar

CONTACT TIME: 5-6 sn

SICAKLIK: 160 °

PRESSURE: 6 bar

SPEED: 3-5 m/min

UZUNLUK: 1 inç 100 m, 3 inç 500/1000/3000 m

*Müşteriye özel uzunlukta üretilebilir.

WIDTH: 160 cm

12 mikron

- Su bazlı tutkal

- Plastik bazlı tutkal

- Solvent bazlı tutkal

- Lazer folyo

- Rotasyon (metraj) baskı

- Serigrafi (parça) baskı

- Sprey uygulaması

Bu hizmet şartları ("Şartlar", "Sözleşme") web sitesi ("Web sitesi operatörü", "biz", "biz" veya "bizim") ile siz ("Kullanıcı", "sen" veya "siz"). Bu Sözleşme, bu web sitesini ve herhangi bir ürününü veya hizmetini (topluca, "Web Sitesi" veya "Hizmetler") kullanımınızın genel hüküm ve koşullarını belirler.

Advantages of Colored Crystal Foil Applications

Without Hot Stamping Foil

Colored crystal foils are produced in colors such as white, black, beige, grey, brown and they can be used in their own colors without colored with hot stamping foils. It saves use of foil.

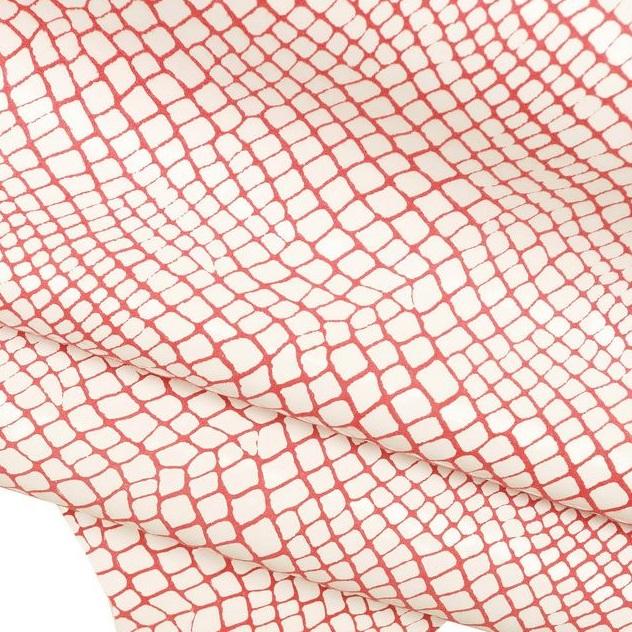

With Transparent Multicolor Foil

Multicolor foils create richness to the surface with patterns consisting of different colors. Transparent multicolored foils fade on the dark surfaces but it can be highlighted with colored crystal foils.

Soft Apperance

While colored crystal foils make the color clear when printed with transparent foils on dark surfaces, they produce soft looking prints on the light colored surfaces.

Transparent &Colored Crystal Foils

To make a comparison, you can see the difference in all cases especially on colored crystal foils with non-metallic foils instead of using transparent crystal foils.

Colored Crystal Foils Printing Stages

1

Crystal Foil Printing

Colored crystal foils are transfered as an adhesive to the fabric by heat pressing the same process as transparent crystal foils.

2

Cooling After Printing

The printed crystal foils are waited for sufficient amount of time to cool or it is cooled rapidly.

3

Carrier Film Peeling

If the printed fabrics are cooled by a cold cylinder then carrier film can be peeled straight away or else fabric should be waited for certain amount of time.

4

Coloring with Foil

Colored crystal foils can be used on its own with its color or it can be colored with transparent foil.

Technical Details to Consider When Applying Crystal Foil

Temperature

Temperature x Pressure x Time

Temperature should be between 125°C-175°C in accordance with the characteristics of the surface to be transferred.

Pressure

Temperature x Pressure x Time

Pressure should decrease as temperature increases. The shrinkage of the carrier film after printing gives the sign.

Contact Time

Temperature x Pressure x Time

Among the factors, the easiest to adjust is always known as contact time (speed in roll to roll printing). It is increased or decreased according to the trial result.

Post Printing

Crystal foil is a hotmelt based feature that melts with heat and solidifies when it cool down. Foil is separated after time cooling or rapid cooling.

Examples of Crystal Foil Printing Machines

Hydraulic Leather Printing Press

It is used in crystal foil applications with high pressure at low temperatures on real leather and suede.

Sublimation Transfer Calender

Although not applying high pressure, complete melting of the crystal foil should be monitored with the correct temperature and contact time.

Roll to Roll Printing Press

Rotopresses developed for hot stamping foil printing are ideal for applying crystal foils to the fabric.

Trouser Transfer Printing Press

Flat air presses used in partial printing provide adequate heat transfer by extending the contact time.

Other Products can be used with Colored Crystal Foil Printing

Transparent Multicolor Hot Stamping Foil

This type of multicolor foils which will reveal the advantages of colored crystal foils, do not suffer from color loss especially when applied to dark fabrics and genuine leathers.

Transparent Hologram Foils (TH) & Oil effect (USF) Foils

To obtain more vibrant colors TH and USF series of foils can be an alternative choice.

General Warnings about Crystal Foil Printing Applications

The information provided on this page about crystal foil printing is for general guidance purposes.

The details given under topics such as application areas, stages of crystal foil printing, technical details to consider and machines used for crystal foil printing may not cover all aspects. Application may require professional machines and expertise.

Even when performed with the same machines, applications depend on specific adjustments and some critical variables. Crystal foil and the application surface are some of them. For example, the temperature rating that is suitable for genuine leather may not be sufficient for transfer to faux suede polyester fabric. To give another example, the application that gives more durable results on washed fabric may give worse results on silicone finished fabrics.

Crystal foil is a hotmelt type of glue and has a structure that freezes when it cools down and melts again at the active temperature and becomes sticky. Crystal foil should mostly be ironed reversely in home ironing, even at single point ironing temperature. Hot stamping foil applied crystal foils are more resistant to heat.

Colored crystal foil applications are easier than traditional printing methods.

Troubleshooting and Technical Information page is for theoretical insights into common issues.

For technical support, feel free to contact our company.

The information provided on this page about crystal foil printing is for general guidance purposes.

The details given under topics such as application areas, stages of crystal foil printing, technical details to consider and machines used for crystal foil printing may not cover all aspects. Application may require professional machines and expertise.

Even when performed with the same machines, applications depend on specific adjustments and some critical variables. Crystal foil and the application surface are some of them. For example, the temperature rating that is suitable for genuine leather may not be sufficient for transfer to faux suede polyester fabric. To give another example, the application that gives more durable results on washed fabric may give worse results on silicone finished fabrics.

Crystal foil is a hotmelt type of glue and has a structure that freezes when it cools down and melts again at the active temperature and becomes sticky. Crystal foil should mostly be ironed reversely in home ironing, even at single point ironing temperature. Hot stamping foil applied crystal foils are more resistant to heat.

Colored crystal foil applications are easier than traditional printing methods.

Troubleshooting and Technical Information page is for theoretical insights into common issues.

For technical support, feel free to contact our company.