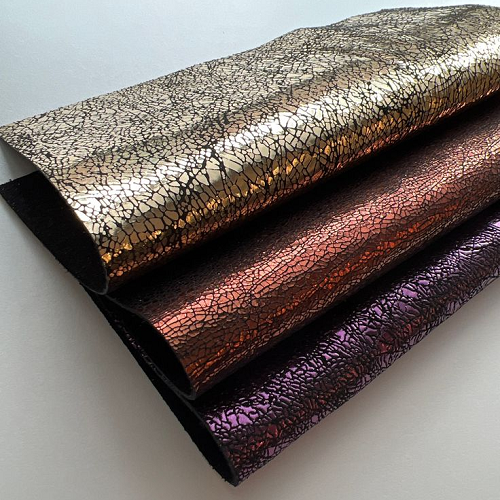

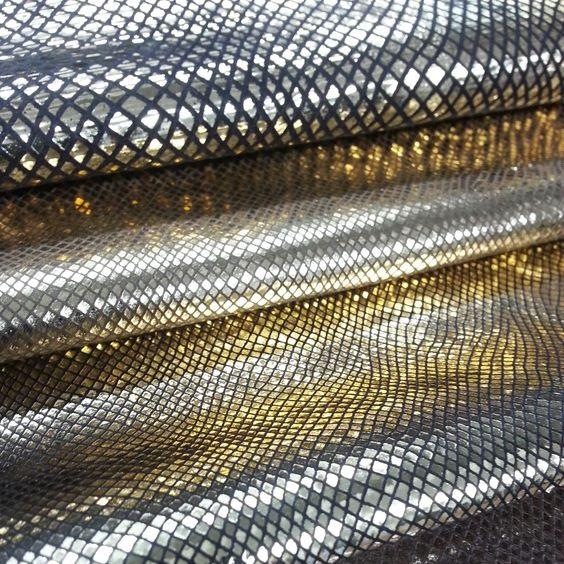

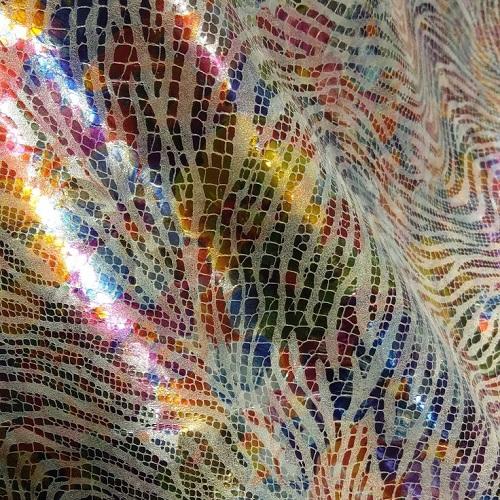

TRANSPARENT CRYSTAL FOILS

Reçine bazlı kimyasal tutkaldan üretilen lazer folyo, baskıya hazır desenli filmlere verilen isimdir. Şeffaf polyester film üzerine hazır kalıplarla aktarılan tutkal, filmin sarılması neticesinde belirli uzunluklara sahip toplar şeklinde kullanıma hazır hale getirilir.

Crystal foils are generally used in the leather and textile sectors. UES offers more than 250 different ready-made patterns and can produce more upon request.

In addition to standard crystal foils; heavy patterned crystal foils are produced with denser resin and offer alternative solutions for different appearances. In addition to glossy carrier films, matt foils are also produced using matt films.

Reçine bazlı kimyasal tutkaldan üretilen lazer folyo, baskıya hazır desenli filmlere verilen isimdir. Şeffaf polyester film üzerine hazır kalıplarla aktarılan tutkal, filmin sarılması neticesinde belirli uzunluklara sahip toplar şeklinde kullanıma hazır hale getirilir.

Genellikle deri ve tekstil sektöründe kullanılmaktadır. UES; 250'den fazla farklı hazır desen sunmaktadır ve talep üzerine daha fazlasını da üretebilir.

Standart lazer folyoların yanı sıra; ağır desenli lazer folyolar, daha yoğun reçine ile üretilerek farklı tutum ve görünümler için alternatif çözümler sunmaktadır. Parlak taşıyıcı filmlerin yanında mat film kullanılarak mat folyolar da üretilmektedir.

TEMPERATURE: 150°C

PRESSURE: 6 bar

CONTACT TIME: 5-6 sec

TEMPERATURE: 160°C

PRESSURE: 6 bar

SPEED: 3-5 m/dk

LENGTH: 3 inch 200 m

WIDTH: 160 cm

Vary between 30 and 200 microns depending on the pattern.

Genuine/suede/nubuck leather

Polyester/cotton based fabrics

Elastic/knitted/woven fabrics

TEMPERATURE: 150°C

PRESSURE: 6 bar

CONTACT TIME: 5-6 sec

SICAKLIK: 160 °

PRESSURE: 6 bar

SPEED: 3-5 m/dk

UZUNLUK: 1 inç 100 m, 3 inç 500/1000/3000 m

*Müşteriye özel uzunlukta üretilebilir.

WIDTH: 160 cm

12 mikron

- Su bazlı tutkal

- Plastik bazlı tutkal

- Solvent bazlı tutkal

- Lazer folyo

- Rotasyon (metraj) baskı

- Serigrafi (parça) baskı

- Sprey uygulaması

Bu hizmet şartları ("Şartlar", "Sözleşme") web sitesi ("Web sitesi operatörü", "biz", "biz" veya "bizim") ile siz ("Kullanıcı", "sen" veya "siz"). Bu Sözleşme, bu web sitesini ve herhangi bir ürününü veya hizmetini (topluca, "Web Sitesi" veya "Hizmetler") kullanımınızın genel hüküm ve koşullarını belirler.

Examples of Crystal Foil Application Areas

Garments

With its elegant touch, durable structure and shiny appearance, crystal foils are used in apparel products, especially leather.

Home Textiles

Crystal foils used in drapery and upholstery fabrics have a different appearance than adhesive or paint printing.

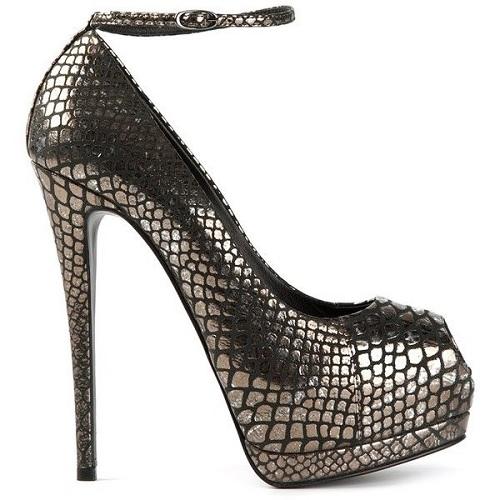

Shoes

Despite having a small surface area, spectacular results can be achieved with crystal foil applied on shoes.

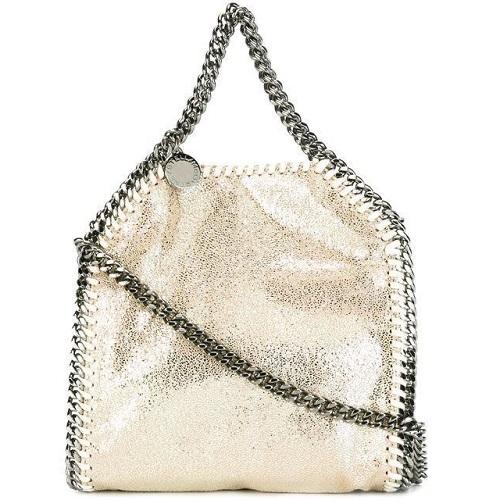

Bags

Crystal foil can be used to add movement and variety to bags made of fabric or leather, in addition to their accessories.

Advantages of Transparent Crystal Foil Applications

High Fastness

High friction and washing fastnesses are achieved with the use of crystal foil.

No Mold Cost

Patterns can be created with crystal foils without the cost of molds. Limited to ready-made patterns.

Flexible Production Quantities

Production with crystal foil not only saves you mold costs but also eliminates the minimum production quantity.

Unique Looks

With crystal foil; brighter, more vibrant and attractive appearances can be achieved compared to standard foil printing on glue.

Transparent Crystal Foils Printing Stages

1

Crystal Foil Printing

The transparent crystal foil, which will replace the glue, is transferred onto the fabric by a heat pressing process.

2

Cooling After Printing

The printed crystal foils are waited for sufficient amount of time to cool or it is cooled rapidly.

3

Carrier Film Peeling

If the printed fabrics are cooled by a cold cylinder then carrier film can be peeled straight away or else fabric should be waited for certain amount of time.

4

Coloring with Foil

Transparent crystal foils can be used on its own with its color or it can be colored with transparent foil.

Technical Details to Consider When Applying Crystal Foil

Temperature

Temperature x Pressure x TimeTemperature should be between 125°C-175°C in accordance with the characteristics of the surface to be transferred.

Pressure

Temperature x Pressure x Time

Pressure should decrease as temperature increases. The shrinkage of the carrier film after printing gives the sign.

Contact Time

Temperature x Pressure x Time

Among the factors, the easiest to adjust is always known as contact time (speed in roll to roll printing). It is increased or decreased according to the trial result.

Post Printing

Crystal foil is a hotmelt based feature that melts with heat and solidifies when it cool down. Foil is separated after time cooling or rapid cooling.

Examples of Crystal Foil Printing Machines

Hydraulic Leather Printing Press

It is used in crystal foil applications with high pressure at low temperatures on real leather and suede.

Sublimation Transfer Calender

Although not applying high pressure, complete melting of the crystal foil should be monitored with the correct temperature and contact time.

Roll to Roll Printing Press

Rotopresses developed for hot stamping foil printing are ideal for applying crystal foils to the fabric.

Trouser Transfer Printing Press

Flat air presses used in partial printing provide adequate heat transfer by extending the contact time.

Other Products can be used with Transparent Crystal Foil Printing

Standard Foils

With its wide range of colours, all standard foils are compatible with crystal foils and suitable for appearances with high friction and washing fastness.

Multicolor Foils

Pattern applications on patterns are one of the most useful methods to increase diversity in the textile and leather industry. Crystal foils and multicolor foils are fully compatible.

Hologram Foils

Because hologram foils are sensitive to heat and may lose color, laser foils are used in low temperature applications.

Total Foils

After the crystal foils are transferred, the spray binder applied on them creates the necessary ground for the skin foils to adhere to. Unique looks are achieved.

General Warnings about Crystal Foil Printing Applications

The information provided on this page about crystal foil printing is for general guidance purposes.

The details given under topics such as application areas, advantages of crystal foil printing, stages of crystal foil printing, technical details to consider and machines used for crystal foil printing may not cover all aspects. Application may require professional machines and expertise.

Even when performed with the same machines, applications depend on specific adjustments and some critical variables. Crystal foil and the application surface are some of them. For example, the temperature rating that is suitable for genuine leather may not be sufficient for transfer to faux suede polyester fabric. To give another example, the application that gives more durable results on washed fabric may give worse results on silicone finished fabrics.

Crystal foil is a hotmelt type of glue and has a structure that freezes when it cools down and melts again at the active temperature and becomes sticky. Crystal foil should mostly be ironed reversely in home ironing, even at single point ironing temperature. Hot stamping foil applied crystal foils are more resistant to heat.

Crystal foil applications are easier than traditional printing methods.

Troubleshooting and Technical Informationpage is for theoretical insights into common issues.

For technical support, feel free to contact our company.

The information provided on this page about crystal foil printing is for general guidance purposes.

The details given under topics such as application areas, advantages of crystal foil printing, stages of crystal foil printing, technical details to consider and machines used for crystal foil printing may not cover all aspects. Application may require professional machines and expertise.

Even when performed with the same machines, applications depend on specific adjustments and some critical variables. Crystal foil and the application surface are some of them. For example, the temperature rating that is suitable for genuine leather may not be sufficient for transfer to faux suede polyester fabric. To give another example, the application that gives more durable results on washed fabric may give worse results on silicone finished fabrics.

Crystal foil is a hotmelt type of glue and has a structure that freezes when it cools down and melts again at the active temperature and becomes sticky. Crystal foil should mostly be ironed reversely in home ironing, even at single point ironing temperature. Hot stamping foil applied crystal foils are more resistant to heat.

Crystal foil applications are easier than traditional printing methods.

Troubleshooting and Technical Informationpage is for theoretical insights into common issues.

For technical support, feel free to contact our company.