PHOTO EMULSIONS

PHOTOCURE WSR (US)-SCREEN PRINTING

Photocure WSR is high resolution emulsion for reproduction of detailed and fine images. Suitable for T-shirt, textile etc., wide range of industries. Suitable for HSA inks and resistant against solvents used during the cleaning process. Applicable also for conventional water based ink and plastisol ink. High solid contents and high viscosity provide excellent coating performance and a flat surface with a lor Rz value. Possible to reclaim.

LP-UB1 - ROTARY PRINTING

LP-UB1 is bichromate free, which is safe and good for environment, and also stable for long storage compared with normal bichromate emulsion. It is for textile printing with rotary screen and suitable for laser-engraving process.

PHOTOCURE WSR (US)-SCREEN PRINTING

Dual Cure (hem kimyasal hem ışıkla polimerize olabilen) doğrudan uygulanabilen foto emülsiyondur. HSA (High Solids Acrylic) su bazlı boyalara uygundur ve temizleme işlemi sırasında kullanılan solventlere karşı dayanıklıdır. Geleneksel su bazlı ve plastisol bazlı boyalara uygundur. Yüksek katı içeriği ve yüksek viskozitesi düşük Rz değeri ile mükemmel kaplama performansı ve düz bir yüzey sağlar. Geri kazanılması mümkündür. Ayrıntılı ve ince görsellerin üretilmesi imkan veren yüksek çözünürlüklü emülsiyondur. Tişört, tekstil vb. birçok sektöre uygundur.

LP-UB1 - ROTARY PRINTING

Rotasyon baskı şablonu emülsiyonudur. Güvenli ve çevre dostudur,

bikromat içermez. Normal bikromat emülsiyonuyla

karşılaştırıldığında uzun süreli saklama açısından stabildir. Lazer gravür işlemi için

uygundur.

WSR: 11.000 mPa.s (25°C)

LP-UB1: 8.000 mPa.s (25°C)

WSR: 1 / 5 kg set

LP-UB1: 1 / 5 kg

MSP-2 / HS-2 / ONE POT / HARDENER-A / HARDENER-B / HARDENER-DL

Examples of Photo Emulsion Application Areas

Partial Printing

There are normal types of emulsion mixed with diazo or high screen emulsions ready for explosure for polyester silk screen used in partial printing.

Rotary Printing

Suitably produced for film, ink and laser exposure for nickel-mesh stencils used in rotary printing. Does not contain bichromate.

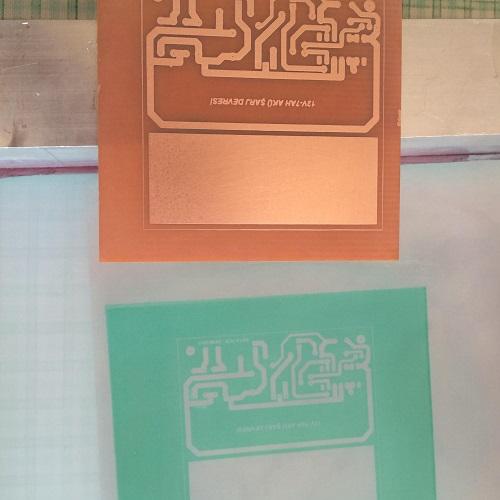

Screen Printing

Photo emulsions are products used in various fields, from solar panel production to electronic printed circuits.

Photo Emulsion Application Stages

1

Mixing with Diazo

Diazo is thoroughly mixed homogeneously into the emulsion with the required amount of water. It should be consumed within a month without light exposure.

2

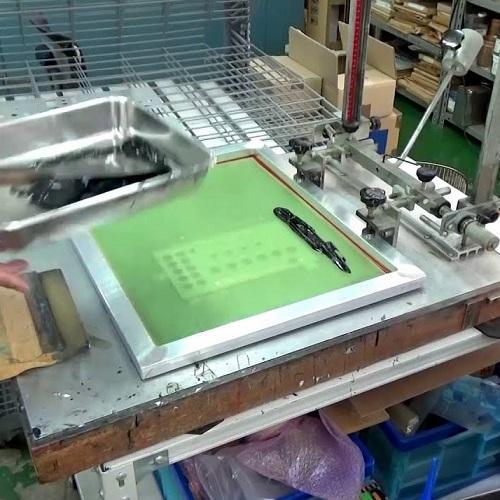

Emulsion Coating

It is kept in a closed box for at least for 1 day to prevent air bubbles resulting from mixing the emulsion. Then it is plastered with silk screen.

3

Drying

The emulsified molds dried for 40 minutes in drying ovens at 40-45 degrees and kept for 1 day before exposure.

4

Exposing

Appropriate exposure time should be adjusted in a few attempts, taking into account that the intensity of the UV lamp may change over time.

5

Developing

While the pattern part is removed from the silk screen with the help of pressurized water after explosure and if there is dissolution in other parts then it means explosure time is not enough.

6

Curing

The mold is opened and water removed, it is made durable by cooking it throughly with UV light. Then it is reinforced with a hardener.

General Warnings about Photo Emulsion Applications

Photo emulsions are produced with light-sensitive chemicals. For this reason, they should be used quickly, especially after mixing with diazo and when it is not in use they should kept closed in their black box away from light and heat.

Photo emulsions are also affected by cold therefore they should never be exposed to freezing temperature and should not kept below +2°C.

The amount of light is highly related to the UV lamp strenght of the device used. Most of the time different brands or different models of emulsions are required to give the same result in the same time. However, while exposure of the photo emulsion for a longer period of time allows more clear patterns to be obtained, emulsion types that exposed in a short period of time can speed up operations. Users should consider the differences in this technique when making their choices.

It is a common mistake to use glass wool or thinner to clean the molds made with photo emulsions produced in accordance with water based or plastisol inks. It damages the emulsions therefore reduces the mold life.

Photo emulsions are produced with light-sensitive chemicals. For this reason, they should be used quickly, especially after mixing with diazo and when it is not in use they should kept closed in their black box away from light and heat.

Photo emulsions are also affected by cold therefore they should never be exposed to freezing temperature and should not kept below +2°C.

The amount of light is highly related to the UV lamp strenght of the device used. Most of the time different brands or different models of emulsions are required to give the same result in the same time. However, while exposure of the photo emulsion for a longer period of time allows more clear patterns to be obtained, emulsion types that exposed in a short period of time can speed up operations. Users should consider the differences in this technique when making their choices.

It is a common mistake to use glass wool or thinner to clean the molds made with photo emulsions produced in accordance with water based or plastisol inks. It damages the emulsions therefore reduces the mold life.