PLOTTER CUT TRANSFER FILMS

Metalik, Yarı Mat, Mat, Hologram ve Camkırığı türlerinde 20'den fazla farklı renk seçeneği mevcuttur.

Plotter cut transfer films are used to transfer plotter cutting machine prepared patterns onto fabric.

Yüksek özellikler ile 20 ve üzerinde yıkamaya dayanıklı olması, düşük adetli üretimlerde kalıp maliyetinden tasarruf sağlar.

Metalik, Yarı Mat, Mat, Hologram ve Camkırığı türlerinde 20'den fazla farklı renk seçeneği mevcuttur.

Plotter kesim makinaları ile hazırlanan desenlerin kumaş üzerine transferi için kullanılır.

Yüksek özellikler ile 20 ve üzerinde yıkamaya dayanıklı olması, düşük adetli üretimlerde kalıp maliyetinden tasarruf sağlar.

TEMPERATURE: 160-170°C

PRESSURE: 4-5 bar

CONTACT TIME: 10-15 sec

Flexy film must be cut from reverse side

Excess parts should be peeled of

Ready to pront motiff should be placed onto base material

Removing the carrier film should be done after cool down

LENGTH: 3 inch 100 m

WIDTH: 150 cm

110 micron

(30 micron transferrable)

Bu hizmet şartları ("Şartlar", "Sözleşme") web sitesi ("Web sitesi operatörü", "biz", "biz" veya "bizim") ile siz ("Kullanıcı", "sen" veya "siz"). Bu Sözleşme, bu web sitesini ve herhangi bir ürününü veya hizmetini (topluca, "Web Sitesi" veya "Hizmetler") kullanımınızın genel hüküm ve koşullarını belirler.

Features of Plotter Cut Transfer Films

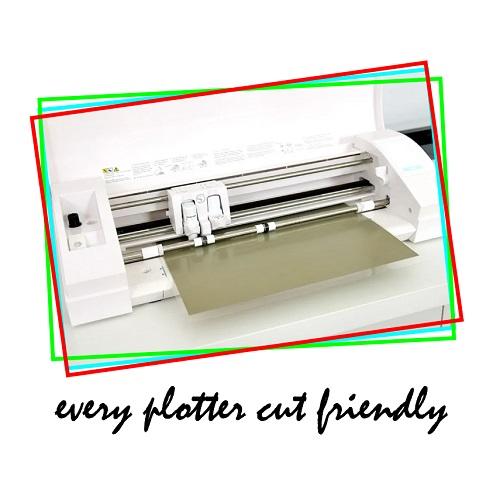

Compatibility

With its specially developed formula and increased strength of carrier film, Flexy is suitable for all brands of plotter cut machines.

Fine Details

Thanks to the specially formulated polyurethane coating, fine details can be obtained with less loss.

Easy Peeling

The balanced adhesion of the carrier film ensures easy peeling after transfer while preserving the color.

Washing Fastness

Specially formulated polyurethane coating enables washing fastness of over 20 times.

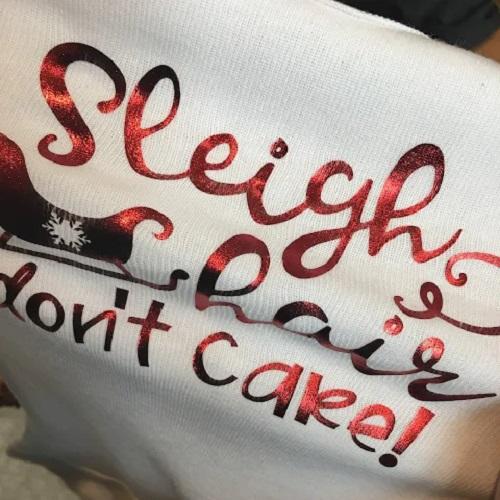

Examples of Plotter Cut Transfer Film Application Areas

Combination Print

Flexy foils can be used on the same material as other traditional screen printing inks without any negative effects.

Textile

Flexy plotter cut foil has become an important printing option in recent years due to its high washing fastness and customization.

Promotion Items

The fact that it can be applied to low volume promotional items with easily designed patterns, enables it to be used in the advertising industry as well.

Accessories

One of the important advantages of flexy plotter cut foils is that they can easily applied directly to sewn or finished products.

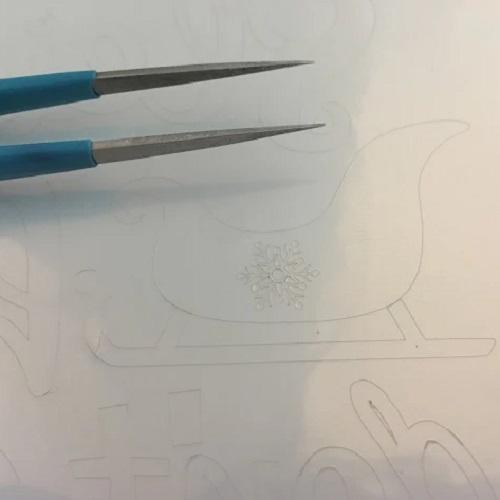

Plotter Cut Transfer Film Printing Stages

1

Cutting

Plotter kesici bıçak takımında en önemli unsur bıçak keskinliği ve doğru açıdır.

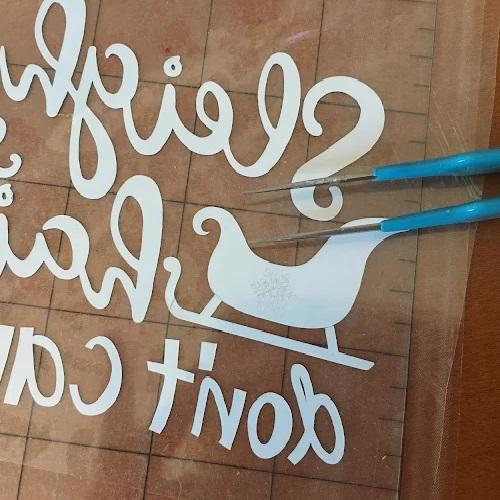

2

Negative Peeling

Proper use of tools such as tweezers, protects the foil to be transferred from deterioration.

3

Carrier Film

After the transfer, peeling the carrier film once cooled well, will provide brighter results.

4

Transfer

Although 160°C temperature, 4 bar pressure and 10 seconds are sufficient for transfer, it can be increased depending on the surface of the materials and pattern type.

Examples of Plotter Cut Transfer Film Printing Machines

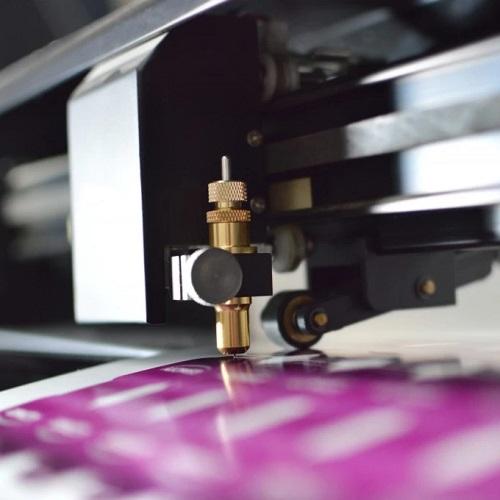

Plotter

Patterns prepared on the computer can be cut from foil with plotters by cutting blades.

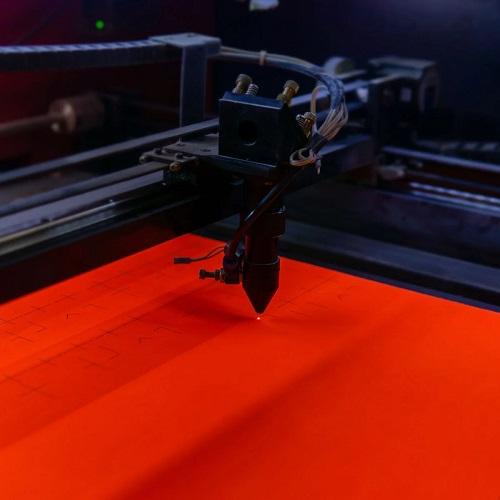

Laser

Printing parts of the foil can be cut with a laser beam of appropriate power without damaging carrier film.

Peeling Tools

Obtaining the fine details without loss is related to the peeling tongs as much as it is to the cutter.

Heat Press

Sufficient heat requirement is only possible with presses that can provide stable temperature and pressure and its contact surfaces are intact.

General Warnings about Plotter Cut Transfer Film Printing Applications

In addition to having a similar appearance to standard hot stamping foils, it offers a durable option for those looking for practical and fast printing with its 80 micron thick heat-resistant carrier film and 30 micron thick polyurethane-based back coating.

The Flexy product is stated to be durable up to 30 washes. Fabric, process method, application parameters, washing test standards can affect the result.

It is recommended that you test it under your own conditions before use.

Home type plotter cutters are also suitable for use.

In addition to having a similar appearance to standard hot stamping foils, it offers a durable option for those looking for practical and fast printing with its 80 micron thick heat-resistant carrier film and 30 micron thick polyurethane-based back coating.

The Flexy product is stated to be durable up to 30 washes. Fabric, process method, application parameters, washing test standards can affect the result.

It is recommended that you test it under your own conditions before use.

Home type plotter cutters are also suitable for use.