HIGH TEMPERATURE DURABLE FOILS

HT Series hot stamping foils are developed for better performance.

HT Series are produced to be resistant to 200-210°C heat with its special chemical design. They show better performance, especially when used with plastisol adhesives.

HT Series have high temperature resistance for stamping at production or ironing later.

HT Series have better wash resistance performance compared to conventional hot stamping foils.

20'den fazla farklı renk seçeneğine ilave olarak şeffaf varak da mevcuttur.

HT serisi varaklar daha iyi performans için geliştirilmiştir.

Özel kimyasal tasarımı ile 200-210°C ısıya dayanıklı olarak üretilmiştir. Özellikle plastisol bazlı tutkallarla kullanımında daha iyi performans göstermektedir.

Üretimde ve ütülemede yüksek sıcaklık dayanımı sağlarlar.

HT serisi, standart varaklara kıyasla daha iyi yıkama direncine sahiptir.

20'den fazla farklı renk seçeneğine ilave olarak şeffaf varak da mevcuttur.

TEMPERATURE: 150°C

PRESSURE: 6 bar

CONTACT TIME: 5-6 sec

TEMPERATURE: 160°C

PRESSURE: 6 bar

SPEED: 3-5 m/min

LENGTH: 1 inch 100 m, 3 inch 500/1000/3000 m

Customer-specific length can be produced upon request

WIDTH: 150 cm

16 micron

Water based adhesives

Plastisol adhesives

Polyurethane adhesives

Crystal foils

Serigraphy prints

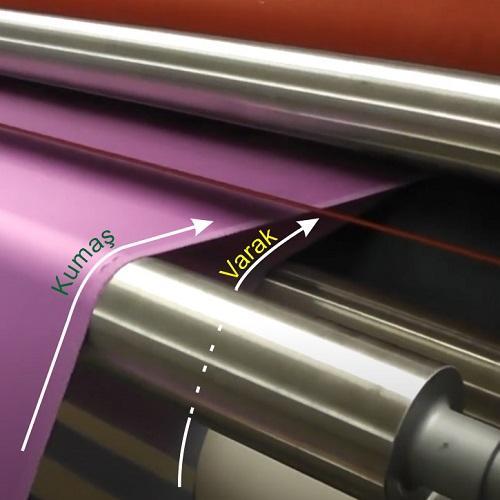

Roll to roll rotary prints

Spray applications

Examples of HT Series Foil Application Areas

Cotton Fabric

HT foils are developed mostly for products that require a high washing resistance such as T-shirts.

Knitwear

Dense glue applied to knitted fabrics gives higher washing fastness on the surface.

Single Jersey

There is no color loss due to high heat in plastisol based adhesive applications.

Denim

HT foils can be applied to all kinds of fabrics like other types of foils and there are no limitations.

Hot Stamping Foil Printing Stages

1

Base Formation

The textile/leather surface is patterned by applying adhesive through screen stencils, rotary templates, spray, engraving cylinders or using crystal foils.

2

Pre-Printing

In partial printing, foil is cut and prepared according to the pattern dimensions. In roll to roll printing, foil is fed with correct tension. Proper transfer requires wrinkle-free foil larger than the adhesive area.

3

Foil Transfer

Parameters are Temperature X Pressure X Time, though recommended by suppliers, depend on the adhesive applied to the fabric/leather and the operational capabilities.

4

Post-Printing

Foils transferred with heat are usually recommended to peeled off the carrier film after cooling. Peeling when it is still hot can sometimes lead to matt appearance due to the adhesive's physical properties.

Adhesive Types Required for Foil Printing

Water Based Adhesive

Water based adhesive are used in partial printing and roll to roll printing as well as in spraying with air gun applications.

Plastisol Adhesive

Plastisol based adhesives used in roll to roll and partial printing to stand out with high wash durability.

Solvent Based Adhesive

Solvent based adhesives, reduced in weight during printing process by removing solvent that produce fine texture and soft handfeeling.

Crystal Foil

Pre-patterned hotmelt adhesive crystal foils are applied to the fabrics as a base for foil application using only heat and pressure.

Adhesive Application Methods

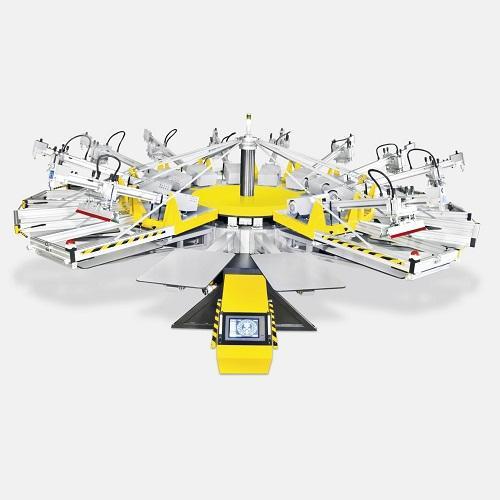

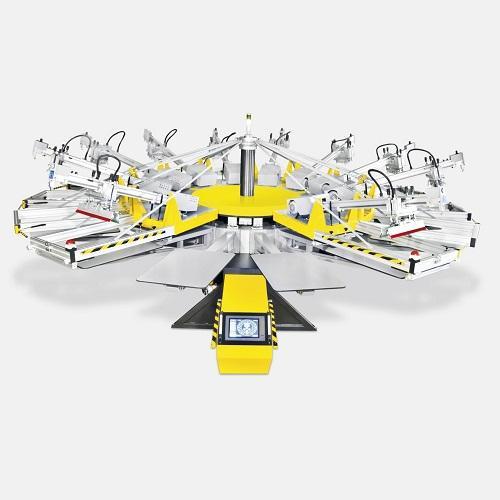

Octopus Printing

Adhesive bases for foil printing can be applied using machines in screen printing workshops for partial printing.

Screen Printing

Manual printing is possible using screen stencils that are used in machine. It is specially used for sample preparation.

Airspray Gun

Water-based adhesives are applied on mostly sewn denim or coats by air spray method.

Rotary Printing

Rotary template stencils used for roll to roll printing in printing and dyeing houses apply adhesives like single headed machines or single color printing.

Examples of HT Foil Printing Machines

Sublimation Press

HT foils can be applied by felt calender that used in sublimation transfer papers printing.

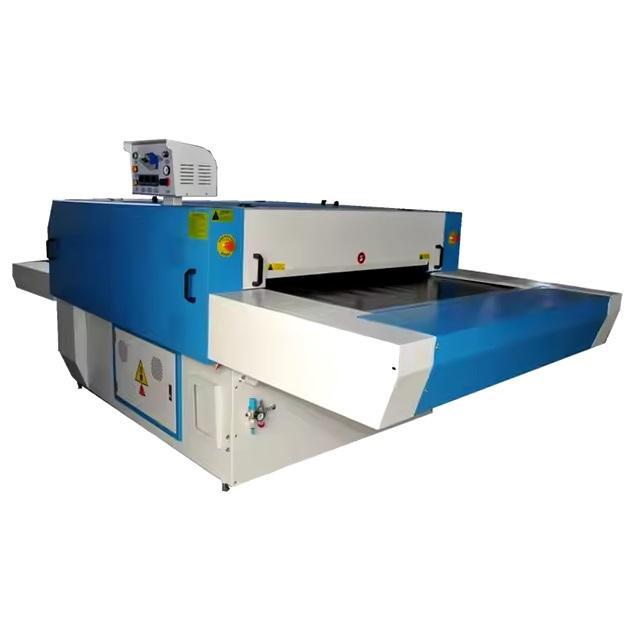

Fusing Press

Fusing presses, indispensable for screen printing workshops, offer ease of use for high-volume partial printing production.

Sliding Press

HT foils can be applied easily on sewn denim pants and coats by using sliding press.

Flat Press

Multifunctional stone presses that are used in small and large printing workshops, are also used for foil printing.

Other Products can be used for Foil Printing

Water Based Adhesives

Suitable for roll to roll and partial printing, and can be applied via spray.

Plastisol Adhesives

It can be used in roll to roll printing and partial printing. It is phthalate-free.

Solvent Based Adhesives

Designed for use in smog gravure printing machine.

Crystal Foils

Pre-patterned hotmelt based foils with high durability.

Squeegee Blades

Used for scraping in rotary and screen printing stencil applications.

Photo Emulsions

For preparing rotary and screen printing stencils.

General Warnings about Foil Printing Applications

The information provided on this page about foil printing is for general guidance purposes.

The details given under topics such as application areas, stages of foil printing, types of adhesives used, adhesive application methods, and machines used for foil printing may not cover all aspects. Application may require professional machines and expertise.

Even when performed with the same machines, applications depend on specific adjustments and some critical variables. These include foil, adhesive, and the surface on which the application is made. For instance; a temperature suitable for cotton fabric may cause shrinkage on polyester fabric or applications yielding more durable results on washed fabrics may perform poorly on silicone coated fabric.

Foil, which do not inherently adhere to fabric or leather but can adhere to the surface they are transferred to, rely on an intermediary adhesive for transfer. The quality of the adhesive, its activation temperature, and parameters such as fixation temperature and duration are critical for achieving the desired result.

Foil printing involves some technical complexity than traditional printing methods. It is often performed by subcontractors rather than integrated facilities such as dyehouses or tanneries. By addressing weak points in this process, predictable results can be achieved with ease.

Troubleshooting and Technical Informationpage is for theoretical insights into common issues.

For technical support, feel free to contact our company.

General Warnings about Foil Printing Applications

The information provided on this page about foil printing is for general guidance purposes.

The details given under topics such as application areas, stages of foil printing, types of adhesives used, adhesive application methods, and machines used for foil printing may not cover all aspects. Application may require professional machines and expertise.

Even when performed with the same machines, applications depend on specific adjustments and some critical variables. These include foil, adhesive, and the surface on which the application is made. For instance; a temperature suitable for cotton fabric may cause shrinkage on polyester fabric or applications yielding more durable results on washed fabrics may perform poorly on silicone coated fabric.

Foil, which do not inherently adhere to fabric or leather but can adhere to the surface they are transferred to, rely on an intermediary adhesive for transfer. The quality of the adhesive, its activation temperature, and parameters such as fixation temperature and duration are critical for achieving the desired result.

Foil printing involves some technical complexity than traditional printing methods. It is often performed by subcontractors rather than integrated facilities such as dyehouses or tanneries. By addressing weak points in this process, predictable results can be achieved with ease.

Troubleshooting and Technical Informationpage is for theoretical insights into common issues.

For technical support, feel free to contact our company.